Add to Cart

Products Name:

High strength welded structure Rustproof Aluminum ship plate 5456 LF10 for ship deck

Products Description (5456 alloys) :

Characters of alloy 5456 :

5456 Application in ship building :

Deck, HIGH-STRENGTH welded structure, tank, pressure vessel, ship material

5456 aluminum Chemical Composition Properties

| Cu | Mg | Mn | Fe | Si | Zn | Ti | Cr | Zr | Al |

| 0.10 | 4.7~5.7 | 0.20~0.6 | 0.40 | 0.40 | - | 0.15 | - | 0.15 | Remainder |

5456 aluminum alloy Mechnical Properties

| Alloy | Tensile Strength σbMpa) | Yield Strengthσ 0.2Mpa) | Enlogation (δ5%) |

| 5456 | ≥420 | ≥275 | ≥10 |

5456 aluminum sheet specification

| Alloy Series | TypIcial Alloy | Typcial Tempe | Thickness (MM) | Width (MM) | Length (MM) |

| 5000 | 5456 | F,H112,F | 3,0~260 | 600~2600 | 1000-24000 |

5456-h116 aluminum SSpecification

| Alloy Series | TypIcial Alloy | Typcial Tempe | Thickness (MM) | Width (MM) | Length (MM) |

| 5000

| 5456 | H111 H116 | 3.0~260 | 1000~4000 | 1000-38000 |

5456 Aluminum Alloy Heat Treatment Specification:

1) Homogenization annealing: heating 480~495℃; heat preservation 12~14h; furnace cold.

2) Full annealing: Heating 390~430℃, holding time 30~120min, furnace cold to 300 ℃, air cooling.

3) Rapid annealing: heating 350~370℃; holding time is 30~120min; air cooling.

4) Quenching and Aging: quenching 495~505℃, water-cooled, artificial aging 185~195℃,6~12h, air cooling, natural aging: room temperature 96h.

ABOUT JIMA Aluminum Services:

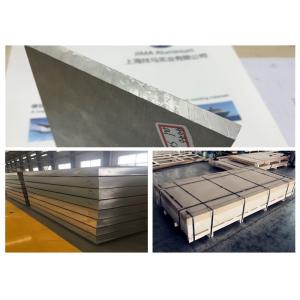

5456 marine grade aluminum plate Photos