Add to Cart

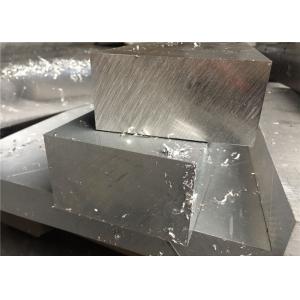

6061 7075 QC-10 Aluminium Tooling Plate 4mm For CNC Milling Purpose

1. Classic alloy type: 6061-T651, 6082-T651, 7075-T651.QC-7,QC-10/ALLCOA

2. Thick plate ,and width and length can be customized

3. Thcikness :4mm-260mm

Introduction:

The density ratio between aluminium and steel is 1:3, and therefore the weight of die can be reduced by 1/2 by using aluminum instead of steel. By using steel-aluminium composite die, the cost of die can be reduced at least 15% as compared to steel die. In addition, the production duration of aluminium die is much shorter than that of steel die, and the processing cost of aluminium die is 35% lower than that of steel die. Therefore, the advantages of aluminium die are obvious.

QC-10 aluminum mold block

As Alcoa’s next generation mold alloy, QC-10 expands mold design options and brings new performance capabilities to high volume manufacturing. It machines 8-10 times faster than steel, reducing finishing costs and lead times by 20-30%.Plus it conducts heat nearly 5 times faster than P-20 tool steel, shorting production cycle times by 20-40%.

Application:

The aluminium products by JIMA can be used in tooling plates, equipment working tables, pharmaceuticals, machining fixtures, computer & electronics, jigs, index tables, mould cooling & heating plates, templates, industrial robot and printing machinery, medical applications, vacuum chucks, food machinery moulding plates, packaging machinery, semi conductor parts, automotive, base plates, thermo forming.

Industrail Moulding and fixture

Product character:

1> high strength,

2> excellent machining performance.